About the company

Bright Day Graphene use a residual product from the forest industry and transform it into a high-quality graphene material, suitable for energy storage and other applications that benefits from the outstanding thermal and electrical conductivity of graphene.

Read more here

Development of a new process for the production of graphene

Work description

As a Process Engineer at Bright Day Graphene, I played a key role in transforming residual products from the forest industry into high-quality graphene material. When I started, the company was still at the research stage and did not have a workflow in place material development and the properties of the material was relatively unknown.My work was separated into two parts: process engineering and scaling of the production line.

Process optimization

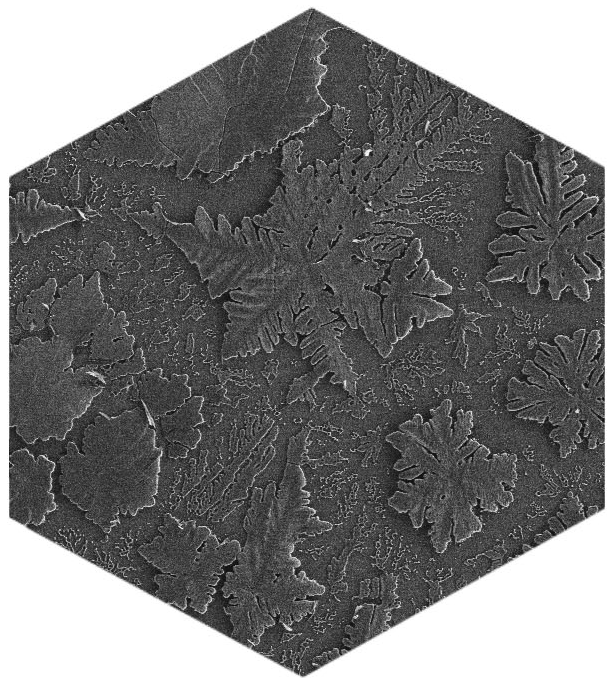

This part of my role was heavily focused on process development, which included working in a lab with electrochemistry and operating high-temperature furnaces for experiments and production. I was responsible for developing and optimizing the process for the production of graphene, including tuning recipes for lignin materials, trying out many different process parameters and testing the quality of the graphene produced. This also included working with SEM and other characterization tools.

Production line scaling

Another key part of my role was to scale up the production line, which included designing the production line from start to finish, ordering and building the equipment and setting up the workflow for the production and testing. This also included producing and delivering samples for customer projects. This involved coordinating with customers to understand their specific requirements, preparing and packaging the graphene samples according to their specifications, and ensuring timely delivery. I also provided technical support and documentation to help customers effectively utilize the graphene samples in their applications. This customer-facing aspect of my role helped me develop strong communication skills and a deeper understanding of the practical applications of graphene in various industries.

Other areas of responsibility included:

As the only employee at the time, I was also responsible for other tasks such as inventory and purchasing of lab equipment.

What I learned in this role:

During my time at Bright Day Graphene, I gained invaluable hands-on experience in graphene production and characterization, developing a deep understanding of process optimization in materials science. I acquired practical knowledge of scaling up laboratory processes to production level, which provided insight into the challenges and opportunities in sustainable materials development. Working in a startup environment enhanced my ability to manage multiple aspects of a business simultaneously. This role significantly improved my problem-solving skills in a research and development context, teaching me to adapt and learn quickly in a rapidly evolving field. I gained expertise in electrochemistry and high-temperature material processing, while also developing a comprehensive understanding of the graphene industry and its applications. Additionally, my project management skills were honed, as I oversaw projects from conceptualization to the delivery of customer samples.

- Advanced materials processing techniques

- Experimental design and analysis in materials science

- Quality control and process optimization

- Collaboration in a research-driven environment

- Understanding of graphene properties and applications

- Sustainable manufacturing practices

Me together with the company's CTO

Graphene produced from lignin