About the company

Mycronic is a world-leading provider of flexible, high-precision production solutions for electronics manufacturing. They strive to keep our customers at the forefront of the industry by offering innovative, sustainable, high-quality production solutions with long product life cycles - solutions designed around the people who use them.

Read more here

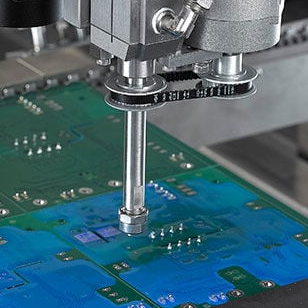

Investigating the impact of printing parameters on jet printing quality

Work description

During my three-month internship at Mycronic, I worked in the physics department, focusing on surface mounting technology (SMT) machines. My project involved investigating how various parameters affect the quality of solder paste droplets on printed circuit boards (PCBs) during the jet printing process. Using high-speed cameras, I captured the behavior of solder paste droplets under different printing conditions. I then developed and implemented image analysis algorithms using MATLAB and Python to process this data. By building statistical models, I analyzed the relationship between printing parameters and droplet quality, aiming to optimize the jet printing process for improved solder joint quality.

Other areas of responsibility

In addition to my main project, I was responsible for maintaining and calibrating the high-speed camera equipment used in the experiments. I also collaborated with other team members to ensure that my findings were integrated into the broader research efforts of the department. Towards the end of my internship, I prepared and delivered a comprehensive presentation of my findings and recommendations to the team, contributing to Mycronic's ongoing efforts to improve their jet printing technology.

What I learned in this role:

This internship provided me with invaluable hands-on experience in a professional R&D environment. I gained deep insights into the intricacies of SMT processes and PCB manufacturing, particularly in the critical area of solder paste application. The project enhanced my skills in experimental design and execution, teaching me how to set up complex imaging systems and design experiments to isolate specific variables. I also significantly improved my programming skills, learning to apply MATLAB and Python to real-world engineering problems. Perhaps most importantly, I developed a keen understanding of how theoretical concepts in physics and engineering translate into practical applications in advanced manufacturing processes.

- Advanced image analysis techniques

- Statistical modeling and data interpretation

- Programming in MATLAB and Python

- Understanding of SMT processes and PCB manufacturing

- Technical presentation and communication skills

- Experimental design and execution in a professional R&D environment

Mycronics high-tech equipment

Jet solder paste for surface mount technology