About the project

My studies in nanotechnology with the focus on nanoelectronics finished with a degree project in engineering physics.

My thesis was carried out at the School of Electrical Engineering and Computer Science (EECS) at KTH Royal Institute of Technology in Stockholm, Sweden.

The supervisors for the project were professor Jiantong Li and PhD student Viktoriia Mishukova. The title of the thesis was "Development and 3D Printing of Intrinsically

Stretchable Materials for Microsupercapacitors" and the projects focused on electrical and mechanical properties of materials that can be used to form supercapacitor structures

in stretchable electronics.

Read my thesis here

Fun fact!

Development and 3D Printing of Intrinsically Stretchable Materials for Microsupercapacitors

Project description

Printed Electronics (PE) is an emerging technology in the field of electronics.

While traditional silicon technologies are predominant in electronics manufacturing, PE has several advantages.

The most important advantage is the relatively simple and cost-effective fabrication methods that are involved in printing electronics [1].

The technology also benefits from having more versatility in terms of available substrate materials.

Another promising feature of PE is that it opens up the possibility of producing stretchable electronics.

Stretchability in this context refers to the ability of an electronic component to retain the performance while a large mechanical strain is applied.

Traditional electronics have relied heavily on silicon substrates and metal interconnects, while PE offers the ability to print stretchable conductive materials on substrates that can be elastically deformed [2].

This opens up a new range of applications such as electronics integrated in clothes or in smart patches that can be placed on the human body.

For stretchable electronics to become fully realized, there is a need to develop stretchable energy storage devices. This project was focused on two parts of this process:

Problem description

Research in printed stretchable energy storage devices has been growing rapidly. The research has been devoted to DIW of energy storage devices and to stretchable electronics respectively. However, combining both technologies into a single method still remains a novel approach, although some research has been conducted on DIW of intrinsically stretchable SCs with promising results. The main difficulty is the development of materials for electrodes and electrolytes that are compatible and have sufficient electrochemical properties. The need for the materials to be stretchable is another obstacle. The problem that will be researched in this thesis is the viability of Direct Ink Writing for fabricating intrinsically stretchable EDLCs.

Experimental

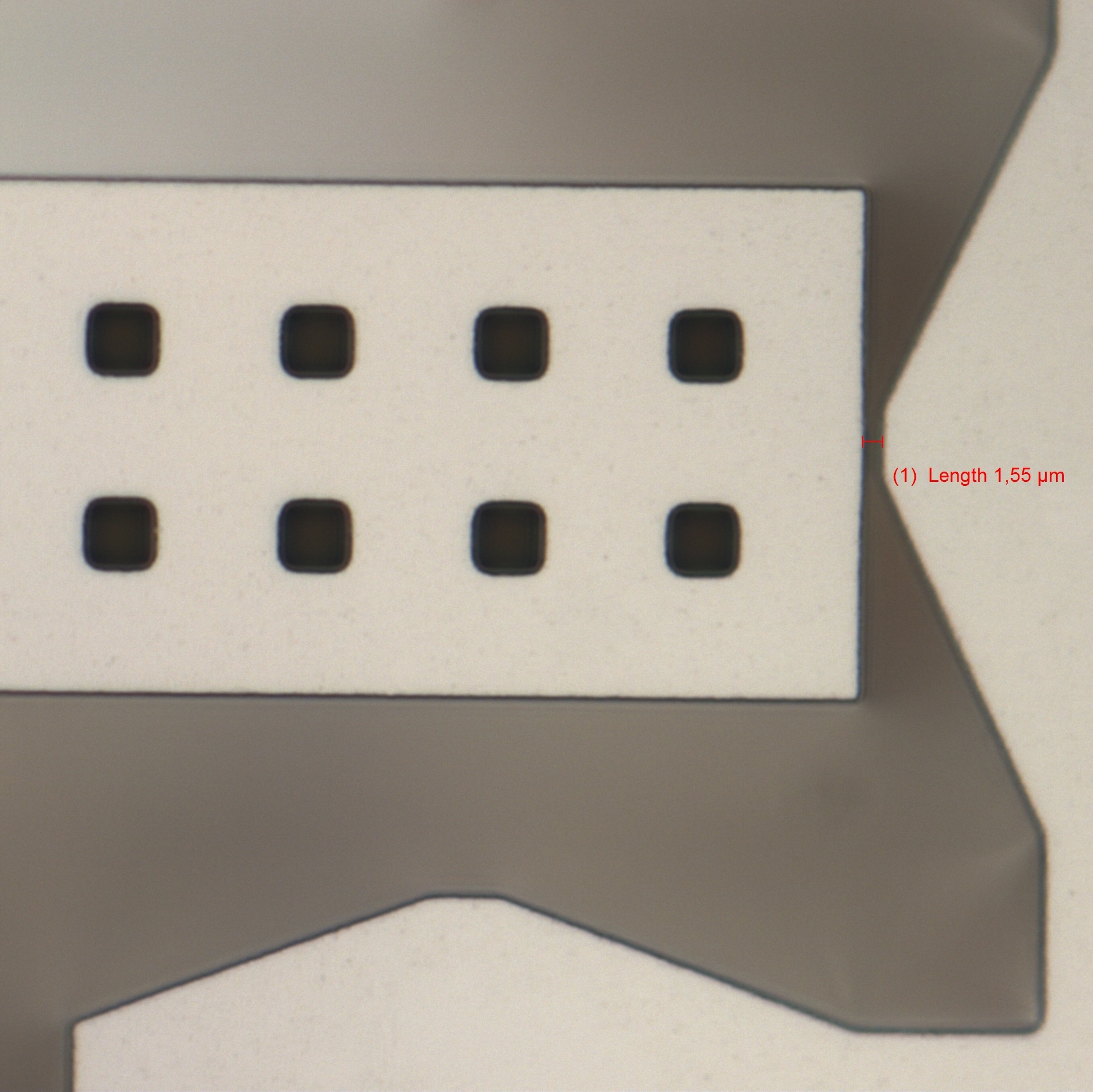

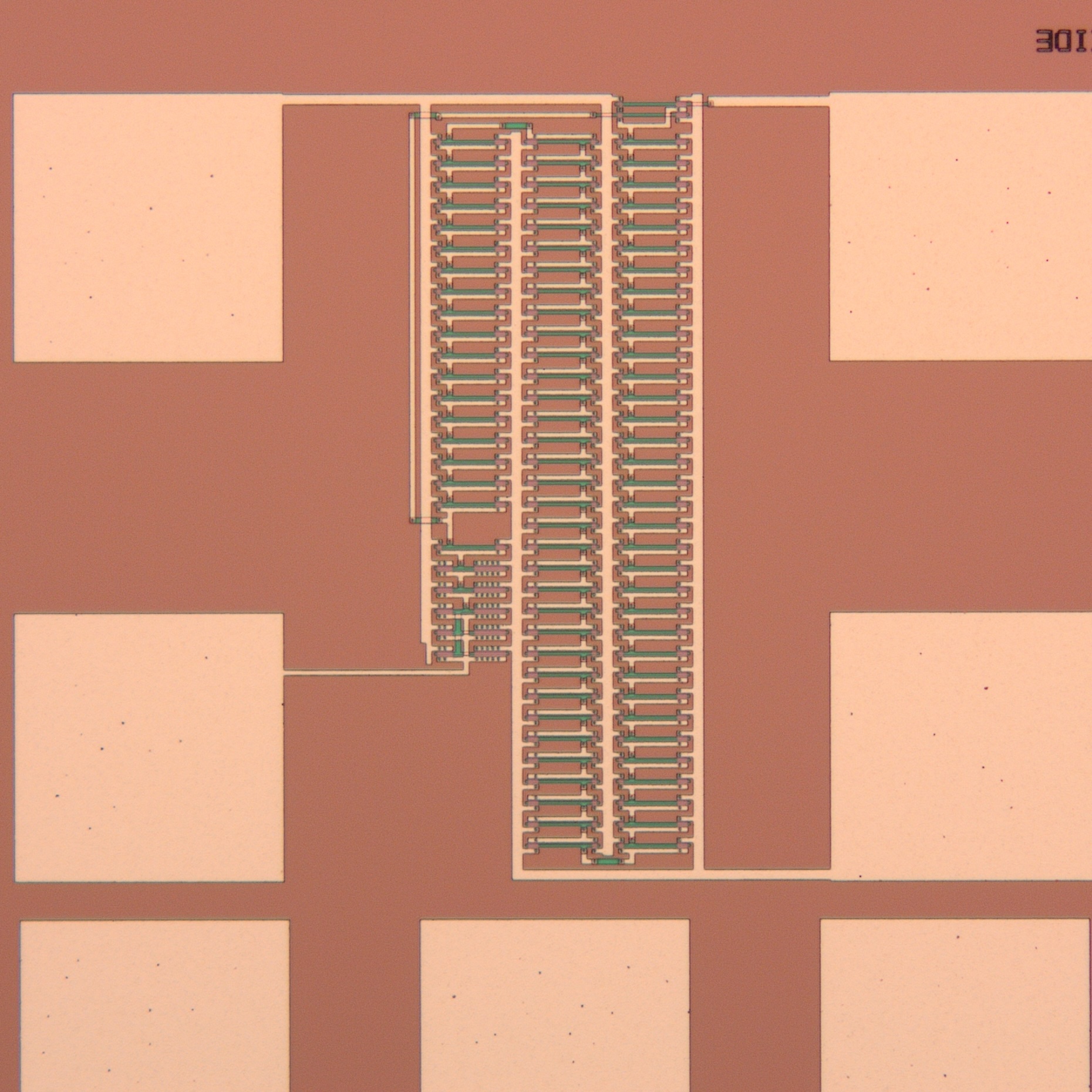

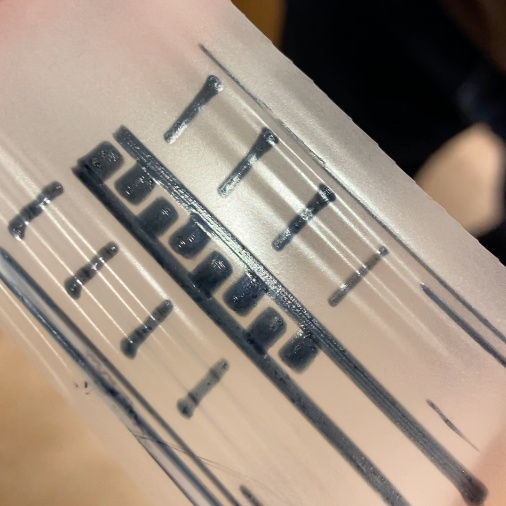

In this thesis, interdigitated structures of intrinsically stretchable electrodes were printed on a stretchable thermoplastic polyurethane (TPU) substrate using a formulated ink based on Poly(3,4-ethylenedioxythiophene):Polystyrene Sulfonate. Formulated electrolytes based on Poly(4-styrene Sulfonic Acid) and Phosphoric Acid were applied to the electrodes to complete the fabrication of microsupercapacitors. Cyclic Voltammetry (CV), Galvanostatic Charge-Discharge (GCD) and Electrochemical Impedance Spectroscopy (EIS) were used to characterize the performance of the devices.

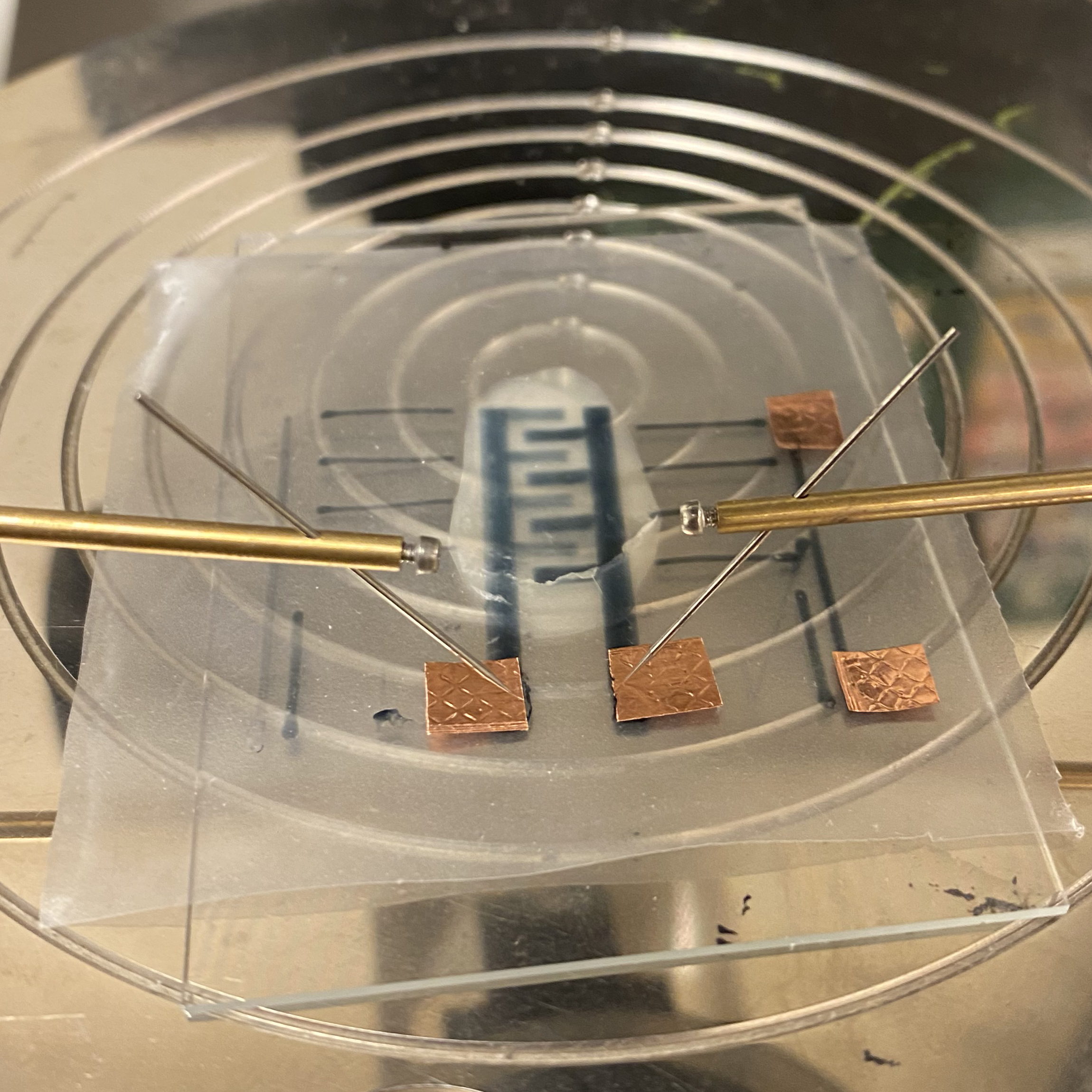

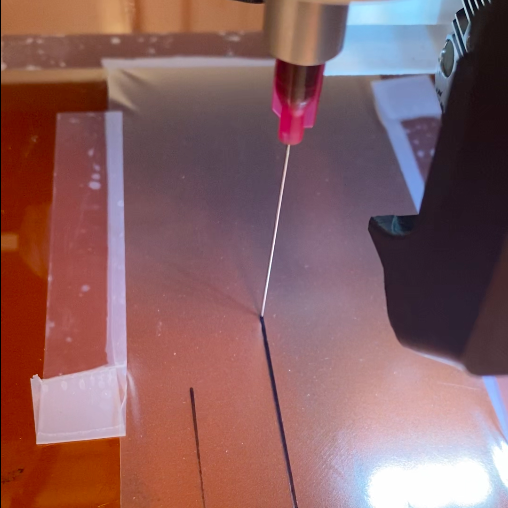

3D printing of the device

Printed device being stretched

Results

Results from CV-measurements revealed a maximum capacitance of 740 µF cm−2 at a scan rate of 5 mV s−1 . GCD-measurements showed a capacitance of 952 µF cm−2 for the same device and an equivalent series resistance of approximately 7 kΩ. The printed electrodes exhibited a stretchability of 80%. The results show the feasibility of fabricating intrinsically stretchable energy storage devices using commercially available materials and a simple 3D printing technique. This method could be used as a high-throughput and low-cost method for stretchable electronics applications.

Contributions to the project:

- Developed a novel Direct Ink Writing (DIW) method for fabricating intrinsically stretchable microsupercapacitors

- Formulated and optimized conductive inks based on PEDOT:PSS for 3D printing applications

- Designed and printed interdigitated electrode structures on stretchable TPU substrates

- Formulated and applied electrolytes to complete the microsupercapacitor devices

- Conducted extensive electrochemical characterization using CV, GCD, and EIS techniques

- Analyzed and interpreted complex electrochemical data to evaluate device performance

- Demonstrated the feasibility of using commercially available materials for stretchable energy storage devices

- Explored the potential of this method for low-cost production of stretchable electronics

What I learned from this project:

This project provided me with invaluable experience in advanced materials research and device fabrication for stretchable electronics.

I gained deep insights into the emerging field of printed electronics, particularly focusing on stretchable energy storage devices.

My understanding of material science expanded significantly, especially in formulating and optimizing conductive inks and electrolytes

for specific applications.

On the fabrication side, I developed expertise in Direct Ink Writing (DIW), a 3D printing technique. I learned to design and

fabricate complex interdigitated electrode structures on flexible substrates, gaining practical knowledge in additive manufacturing

for electronics. This experience enhanced my problem-solving skills in real-world engineering challenges, particularly in

optimizing printing parameters and material properties for desired performance.

My proficiency in electrochemical characterization techniques grew substantially. I became adept at using Cyclic Voltammetry (CV),

Galvanostatic Charge-Discharge (GCD), and Electrochemical Impedance Spectroscopy (EIS) to evaluate device performance. This

experience significantly improved my data analysis and interpretation skills, enabling me to extract meaningful insights from

complex electrochemical datasets.

The project also honed my research skills, teaching me how to design experiments, troubleshoot issues, and iterate on designs

to improve performance. I learned to balance theoretical understanding with practical implementation, a crucial skill in

materials science and engineering. It provided me with a comprehensive understanding of the

research process in an academic setting and prepared me for future challenges in advanced materials and device engineering.

Working on this cutting-edge topic exposed me to the broader implications of stretchable electronics, including potential

applications in wearable technology and smart textiles. It taught me to think creatively about how to address challenges in

this emerging field and to consider the practical aspects of transitioning laboratory research into real-world applications.